Web Menu

Product Search

Exit Menu

How does a butterfly-shaped lead-in cable maintain transmission stability in a complex wiring environment?

How does a butterfly-shaped lead-in cable maintain transmission stability in a complex wiring environment?

The butterfly-shaped lead-in cable, also known as a sheath cable or FTTH cable, is named after its unique flattened design, with a cross-section that resembles a butterfly. This design not only makes the cable more beautiful in appearance, but more importantly, it greatly improves the adaptability and flexibility of the cable in a complex wiring environment.

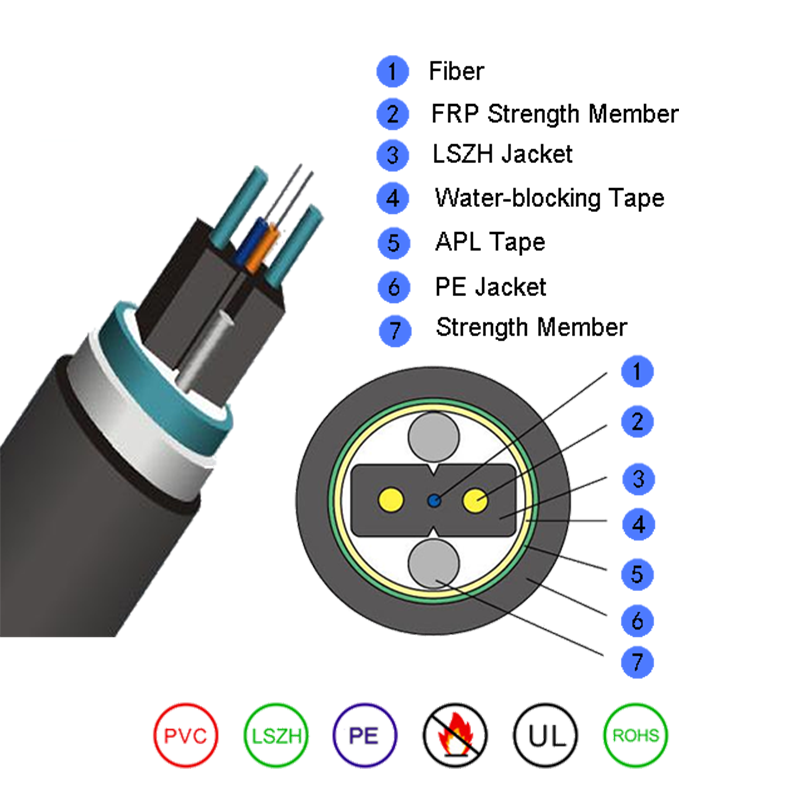

However, the advantages of a bow-type drop cable for duct are not limited to its appearance. The careful design of its internal structure is the key to its ability to maintain transmission stability in a complex wiring environment. Specifically, a reinforcing core and a special sheath structure are provided inside the butterfly-shaped lead-in cable.

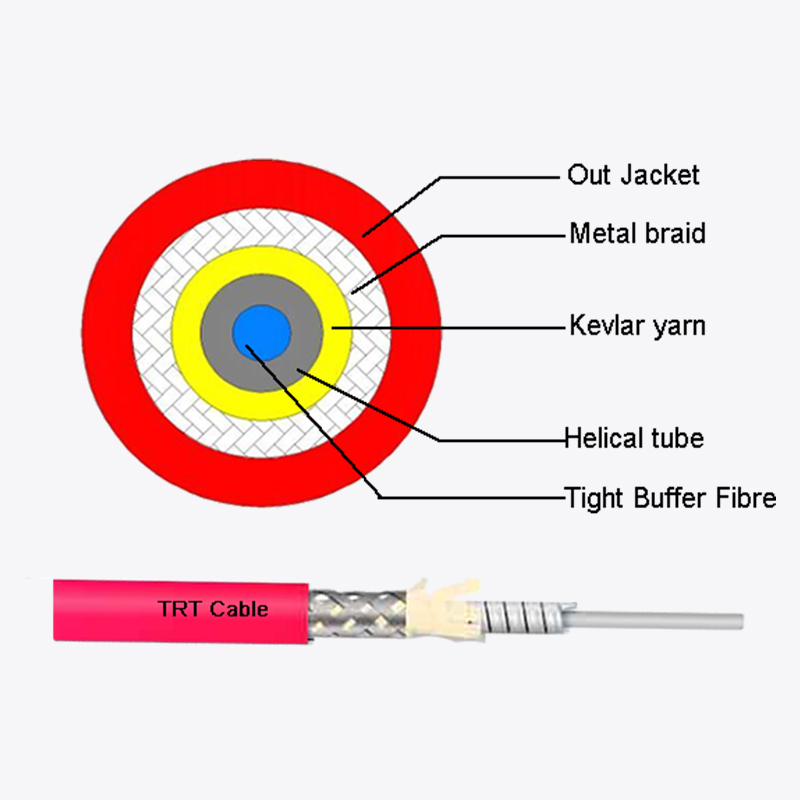

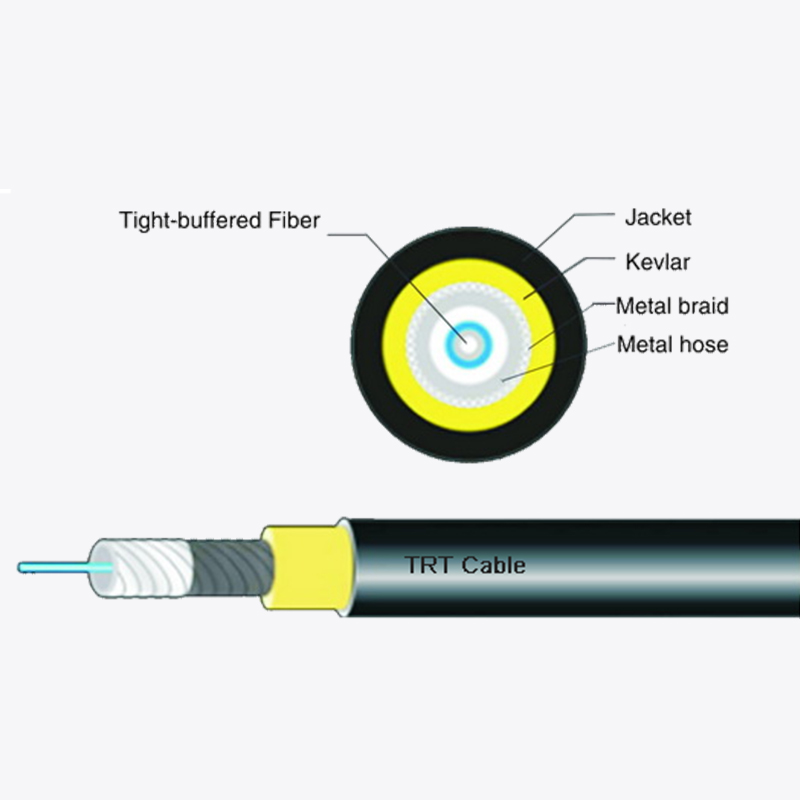

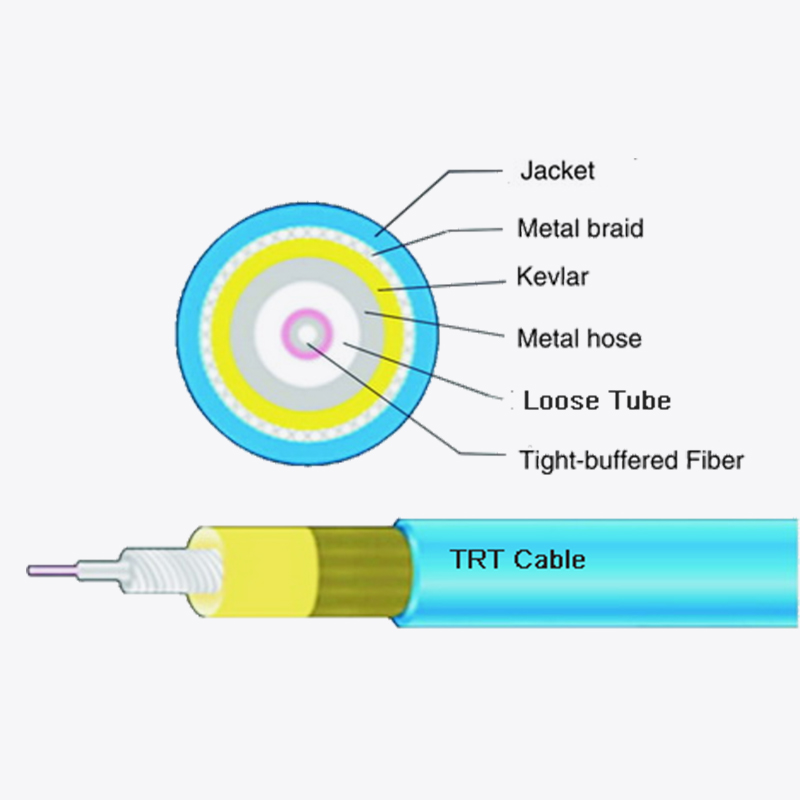

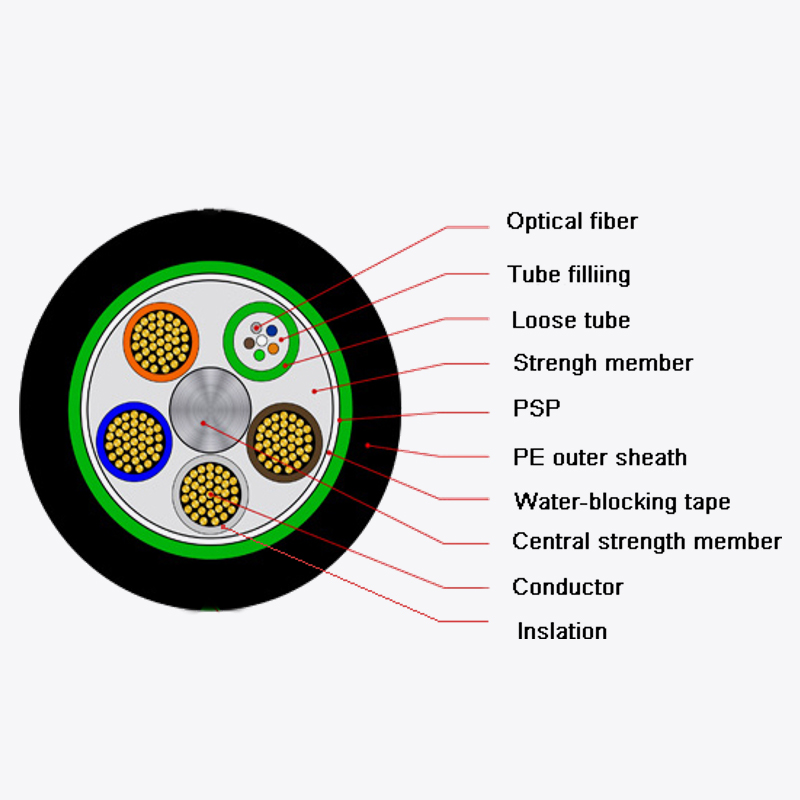

The reinforcing core is usually made of high-strength, high-modulus materials, such as glass fiber reinforced plastic (GFRP) or aramid fiber (Kevlar). It is located in the center or on both sides of the cable, providing the cable with strong tensile resistance. During the wiring process, the cable may be subjected to various tensile forces, such as pipe bending, building settlement, etc. The presence of the reinforcing core enables the cable to maintain its shape under these tensile forces, thereby ensuring that the transmission performance of the optical fiber is not affected.

The special sheath structure is the key to the lateral pressure resistance of the butterfly-shaped lead-in cable. The sheath is usually made of materials such as polyethylene (PE), polyvinyl chloride (PVC) or low-smoke zero-halogen (LSZH), and has excellent wear resistance, corrosion resistance and flame retardant properties. More importantly, the inside of the sheath is usually filled with special buffer materials, such as gel or foam, which can play a buffering role when the optical cable is subjected to lateral pressure and protect the optical fiber from damage.

In the pipeline wiring environment, the optical cable needs to face a variety of complex mechanical stresses. These stresses may come from the bending of the pipeline, the settlement of the building, and the collision during the construction process. These stresses will not only damage the physical structure of the optical cable, but more importantly, they may affect the transmission performance of the optical fiber, causing signal attenuation, distortion or interruption.

The butterfly-shaped lead-in cable successfully copes with these challenges through its internal reinforcement core and special sheath structure. The reinforcement core provides the optical cable with strong tensile resistance, allowing the optical cable to maintain its shape under tensile force. The special sheath structure provides the optical cable with excellent lateral pressure resistance through its internal buffer material. Even when subjected to strong lateral pressure, the sheath can protect the optical fiber from damage, thus ensuring stable signal transmission.

The technical principles behind the butterfly-shaped lead-in cable's ability to maintain transmission stability in complex wiring environments are mainly based on the following points:

Tensile performance of the reinforcing core: The reinforcing core is usually made of high-strength, high-modulus materials, such as GFRP or Kevlar. These materials have excellent tensile properties and can withstand huge tensile forces without deformation. When the optical cable is subjected to tensile force during the wiring process, the reinforcing core can maintain the shape of the optical cable unchanged, thereby ensuring that the transmission performance of the optical fiber is not affected.

Side pressure resistance of the sheath: The buffer materials inside the sheath, such as gel or foam, have excellent buffering and energy absorption properties. When the optical cable is subjected to lateral pressure, these materials can absorb and disperse the pressure, thereby protecting the optical fiber from damage. The sheath material itself also has excellent wear resistance, corrosion resistance and flame retardant properties, which can further improve the durability and safety of the optical cable.

Optical fiber protection and transmission performance: The optical fiber inside the butterfly-shaped lead-in cable is usually protected by a loose tube or a tight package structure. The loose tube structure can provide a larger buffer space for the optical fiber, while the tight package structure can reduce the size and weight of the optical cable. These protective measures can not only improve the damage resistance of the optical fiber, but also ensure the stability and reliability of the optical fiber during transmission.

Based on the above technical principles, the butterfly-shaped lead-in optical cable has shown significant performance advantages in complex wiring environments. It can not only withstand greater mechanical stress, but also maintain stable transmission performance. This means that in the pipeline wiring environment, the butterfly-shaped lead-in optical cable can provide users with more reliable and efficient network services.

The application advantages of the butterfly-shaped lead-in optical cable in complex wiring environments are mainly reflected in the following aspects:

Improve wiring efficiency: The flat design and compact size of the butterfly-shaped lead-in optical cable make it more suitable for wiring in narrow spaces. This not only improves wiring efficiency, but also reduces wiring costs.

Enhance network stability: The tensile and lateral pressure resistance of the butterfly-shaped lead-in optical cable enables it to maintain stable transmission performance in complex and changeable wiring environments. This provides users with more reliable and efficient network services.

Reduce maintenance costs: The durability and safety of the butterfly-shaped lead-in optical cable enable it to reduce failure rates and maintenance costs during long-term use. This saves users a lot of time and money.

Looking to the future, with the continuous advancement of communication technology and the continuous expansion of application scenarios, butterfly-shaped optical cables are expected to play an important role in more fields. For example, in the fields of smart cities, smart homes, industrial automation, etc., butterfly-shaped optical cables will provide users with more efficient and convenient network services. With the continuous development of new technologies such as 5G and the Internet of Things, butterfly-shaped optical cables will also usher in a broader market prospect.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى