Web Menu

Product Search

Exit Menu

Why has the reinforcing core become an indispensable core component of FTTH drop cable?

Why has the reinforcing core become an indispensable core component of FTTH drop cable?

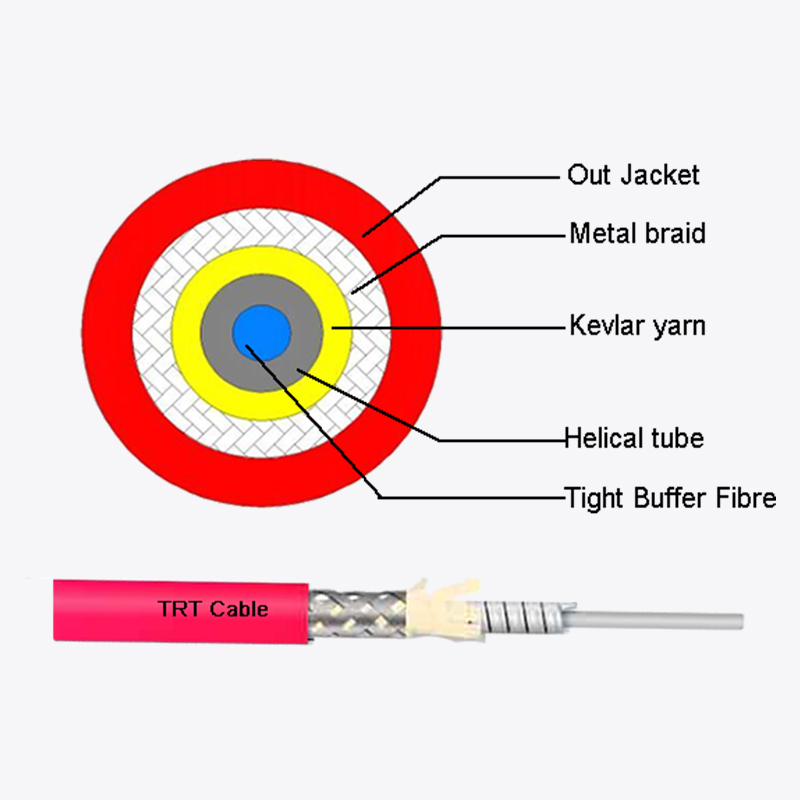

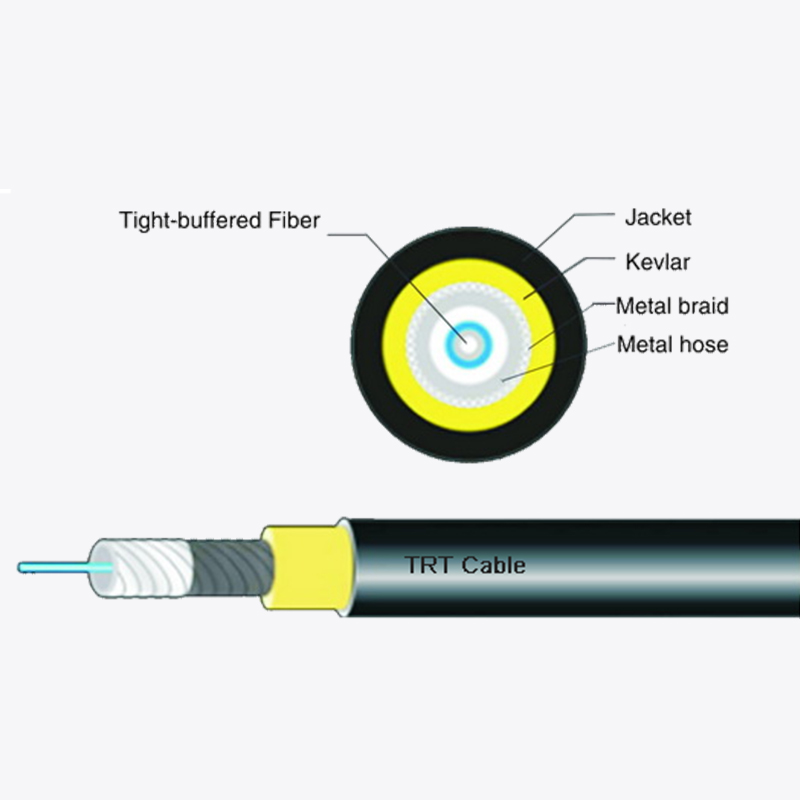

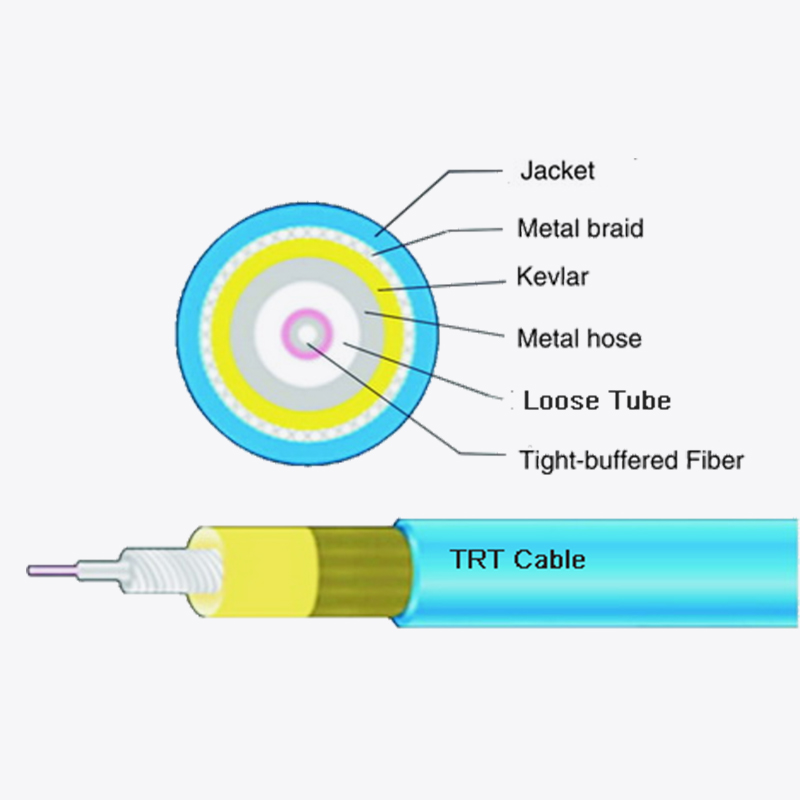

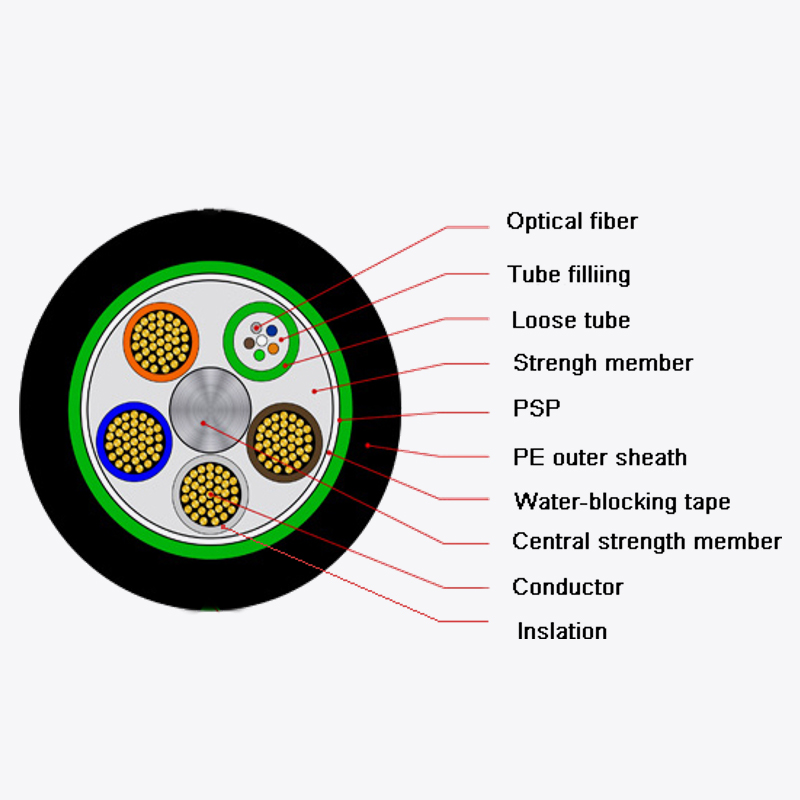

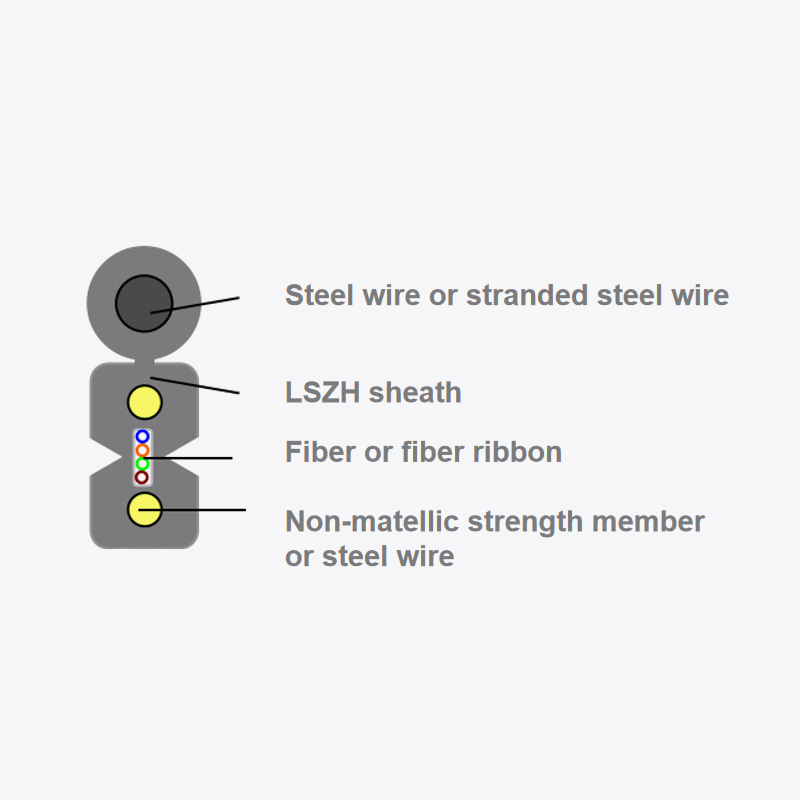

FTTH drop cable usually contains multiple components such as optical fiber, reinforced core, metal shielding layer and sheath. Among them, optical fiber is the medium for signal transmission, and its quality and location are crucial to transmission performance. However, the optical fiber itself is fragile and susceptible to physical damage. Especially in complex and changeable installation environments, such as through walls, wiring ducts, and underground burials, optical fibers are more susceptible to external forces such as stretching, bending, and extrusion. influence. In order to effectively protect optical fibers and improve the overall mechanical properties of the cable, the introduction of reinforced cores is particularly important.

The stiffening core is located around the fiber and provides additional mechanical support to the cable. It is usually made from high-strength, low-weight materials such as aramid fiber or fiberglass. These materials not only have excellent mechanical properties, such as high strength, high modulus, low density and good corrosion resistance, but also have good thermal and chemical stability, allowing them to maintain stable performance in extreme environments. Through careful design and precise control of the shape, size and position of the reinforcing core, the cable's tensile resistance, bending resistance and extrusion resistance can be significantly enhanced, thereby effectively protecting the optical fiber from physical damage.

In terms of material selection for the reinforced core, aramid fiber and glass fiber each have their own merits. Known for its high strength, high modulus, low weight and excellent thermal stability, aramid fibers can withstand extremely high tensile and compressive stresses while maintaining good flexibility. This makes aramid fibers an ideal material for manufacturing high-performance reinforcing cores, especially in applications where it is necessary to withstand high mechanical stresses and maintain low weight. However, the relatively high cost of aramid fibers limits their widespread use in certain economically sensitive applications.

In contrast, fiberglass has the advantages of low cost, easy processing, chemical resistance and good insulation properties. Although its strength and modulus are slightly lower than aramid fiber, in many FTTH drop cable application scenarios, the performance of glass fiber is sufficient to meet the requirements. In addition, glass fiber also has good weather resistance and flame retardant properties, which can further improve the safety and service life of cables. Therefore, fiberglass has become a popular choice when seeking a balance between cost-effectiveness and performance requirements.

The introduction of reinforced cores has a profound impact on the performance of FTTH drop cables. First of all, it significantly enhances the mechanical properties of the cable and improves the cable's resistance to stretching, bending and extrusion. This enables the cable to maintain structural integrity and stability in complex and changeable installation environments, and effectively prevents optical fibers from being damaged by external forces. Secondly, the reinforced core also improves the durability of the cable and extends its service life. During long-term operation, the reinforced core can provide stable support and protection for the cable even when faced with challenges from erosion by various environmental factors and mechanical stress.

The introduction of reinforcing cores also has a positive impact on the transmission performance of the cable. By optimizing the design and material selection of the reinforcing core, the bending radius and bending loss of the cable can be reduced, thereby improving the transmission efficiency and bandwidth utilization of the optical fiber. At the same time, the reinforced core can also improve the electrical performance of the cable, such as reducing capacitive coupling and inductive coupling effects, and reducing signal interference and attenuation. These performance improvements enable FTTH drop cables to better adapt to high-speed, high-bandwidth network transmission requirements.

Although the reinforcing core plays a vital role in FTTH drop cables, it still faces some challenges during practical application. For example, the introduction of a reinforcing core may increase the diameter and weight of the cable, thereby increasing installation difficulty and cost. To solve this problem, new materials and structural designs can be used to reduce the weight and diameter of the cable. At the same time, by optimizing the production process and quality control process, the adhesion and consistency between the reinforced core and the optical fiber, metal shielding layer and sheath can be improved, thereby improving the overall performance and reliability of the cable.

The material selection and size design of the reinforcing core also need to be customized according to the specific application scenario. For example, in scenarios that need to withstand large mechanical stress, high-strength, high-modulus aramid fiber can be selected as the reinforcing core material; while in cost-sensitive applications, more cost-effective glass fiber can be selected. By comprehensively considering factors such as application scenarios, performance requirements, and cost-effectiveness, the optimal reinforcement core design can be developed.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى