ABOUT US

Suzhou TeRuiTong Communication Co., Ltd.

Suzhou TeRuiTong Communication Co., Ltd. is China wholesale Waterproof Pig-tail fiber optic cable GJA manufacturers and Waterproof Pig-tail fiber optic cable GJA factory, located in the Wuzhong District, Suzhou, Jiangsu Province, China. It specializes in producing all kinds of indoor optical cables and also can develop the products according to customers' requirements. Our main products include indoor cable, outdoor cable, FTTH cable, flexible metal armored cable, a range of jumper wires and cable accessories which are all with the ISO9001&ISO14000 QS Certification.

The products are widely used in various fields, such as the computer room's construction of China Telecom and China Mobile, the networking engineering of buildings, the radio network, defense communications and shipping communications. We are introduced to the following fields civil engineering, bridge construction, electric power systems, subway temperature and straining sensing through wide sensor equipment and professional communication companies. We offer Waterproof Pig-tail fiber optic cable GJA for sale. We are confident that we have the experience to be your long-term strategic partner. Let us join hands and build a brighter future!-

The zipcord Interconnect fiber optic cable is a widely used component in telecommunications, data centers, and networking environments due to its simp...

READ MORE -

Splicing tight buffer fiber optic cable is a fundamental process in fiber optic network installations. The process ensures continuous optical signal t...

READ MORE -

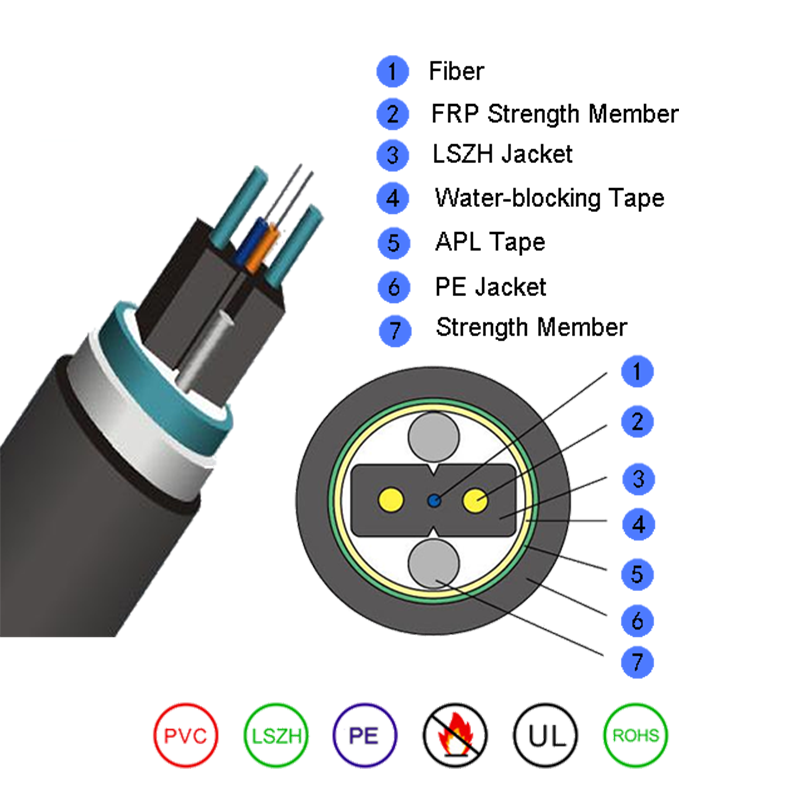

Ensuring that a waterproof pig-tail fiber optic cable meets outdoor installation requirements is a critical consideration for telecommunications, netw...

READ MORE -

Self-supporting Round fiber optic cable has become a critical component in modern fiber optic networks, particularly for outdoor and aerial applicatio...

READ MORE

Further negotiation?

We are glad to hear from you.

Build A Partnership With Us With Our Industry Insight!

and strategic vision!

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى-1.png)

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:

Email: