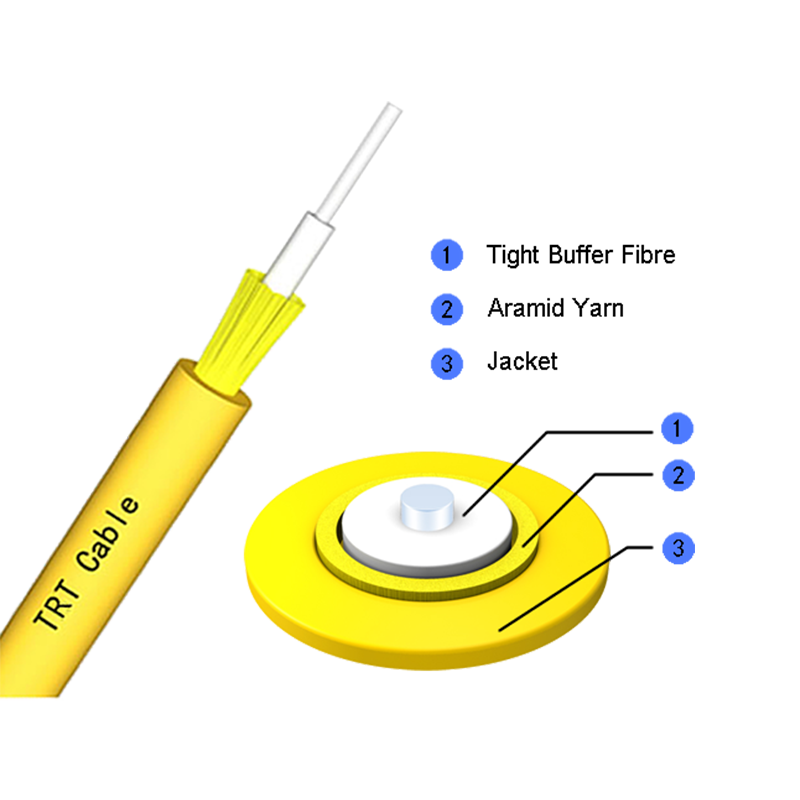

Tight Buffer fiber optic cable TBF(GJI)

Simplex fiber optic cable GJFJ

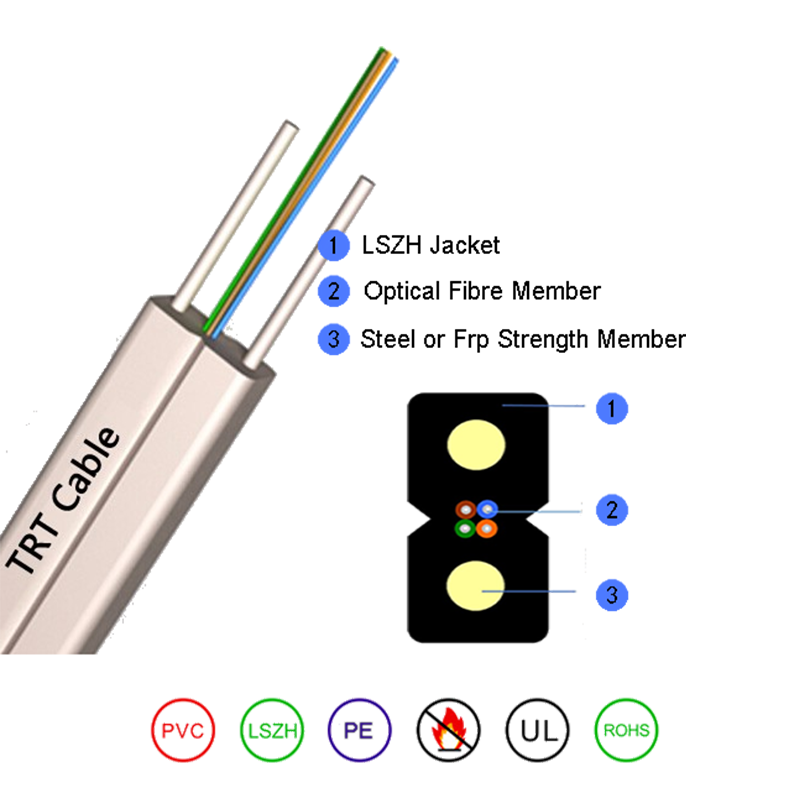

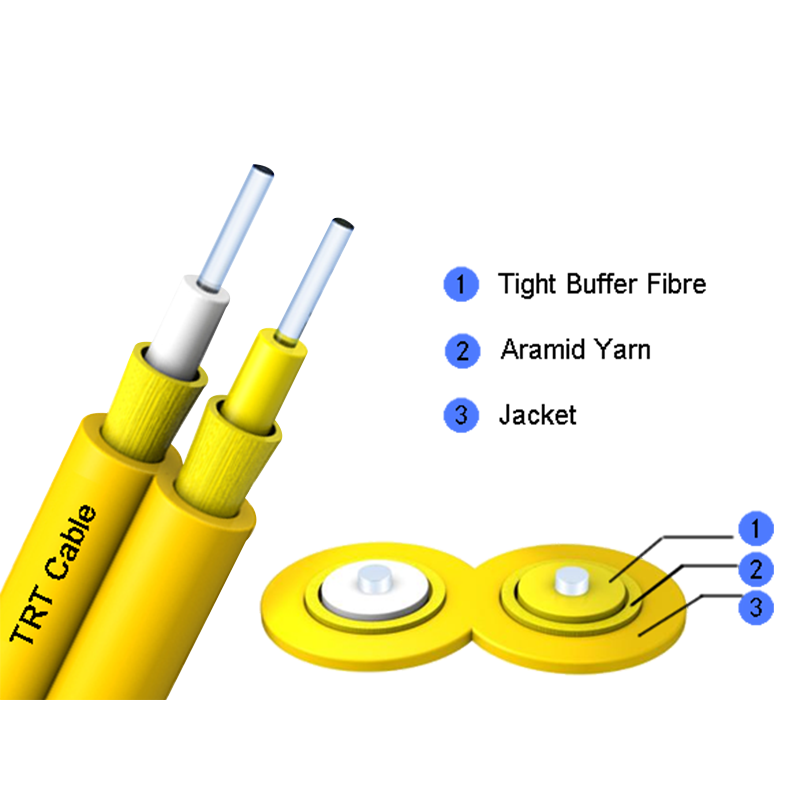

Zipcord Interconnect fiber optic cable GJFJB

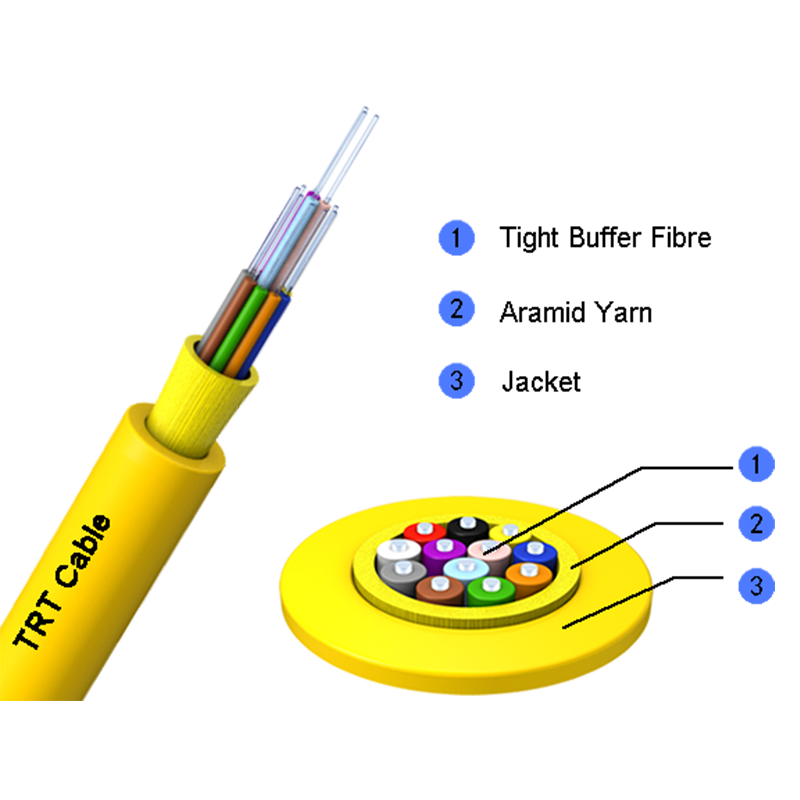

Multi-Purpose Break-out fiber optic cable GJBFJ

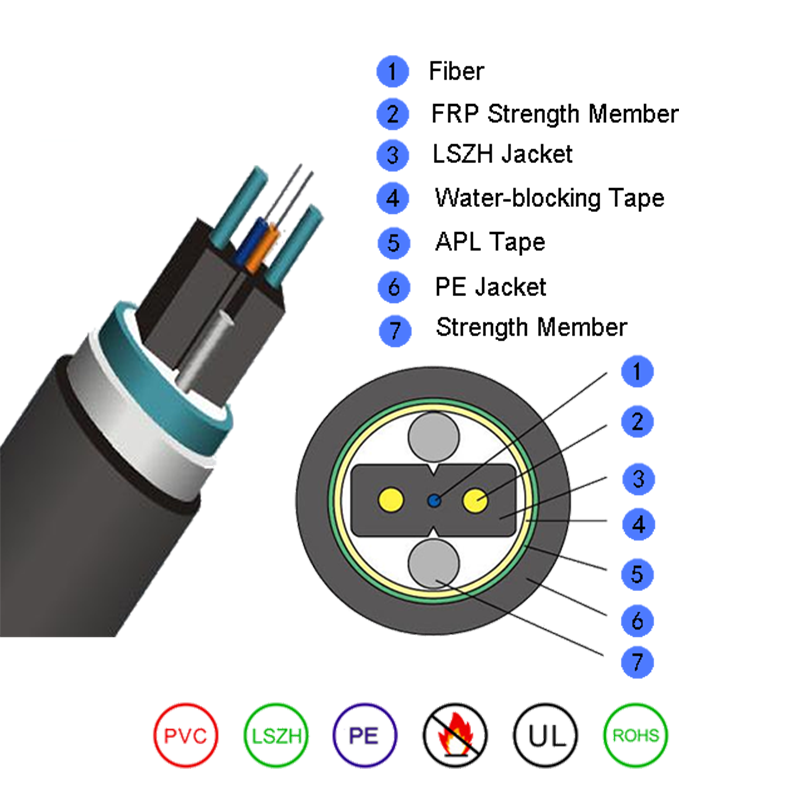

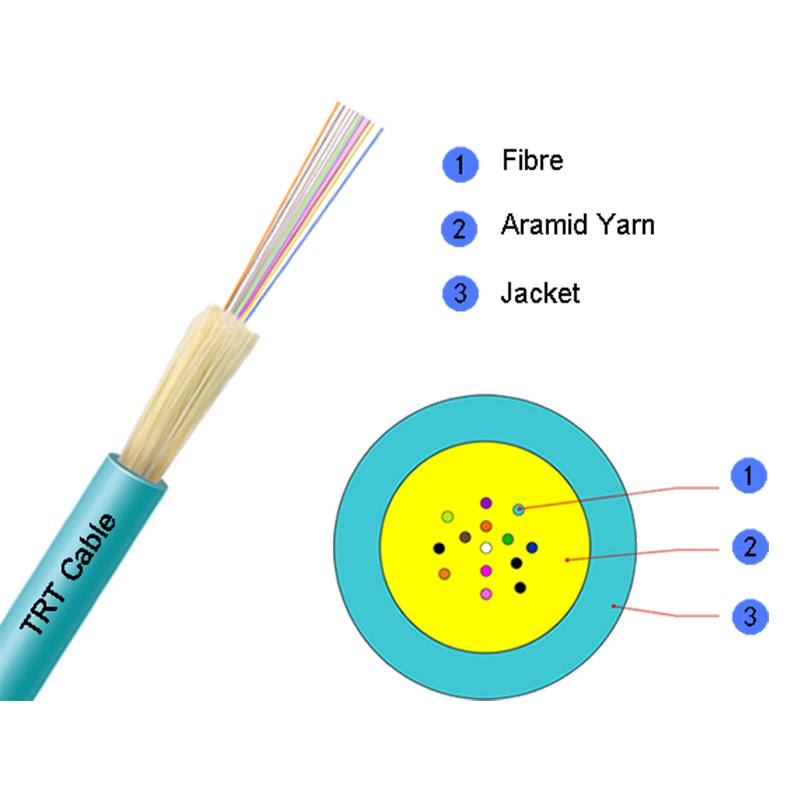

Multi-Purpose Distribution Cable MPC≤24f

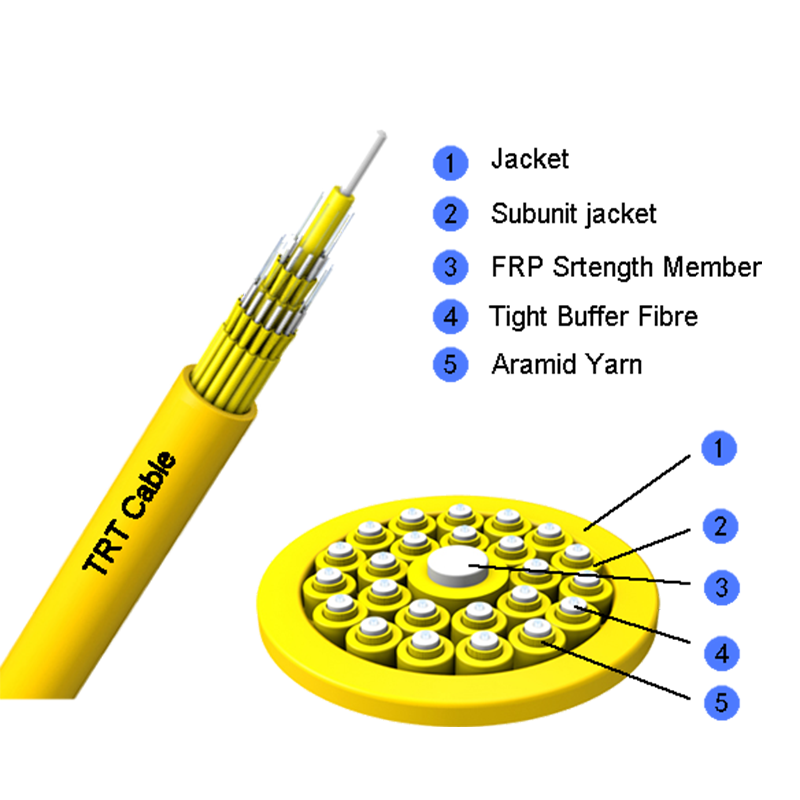

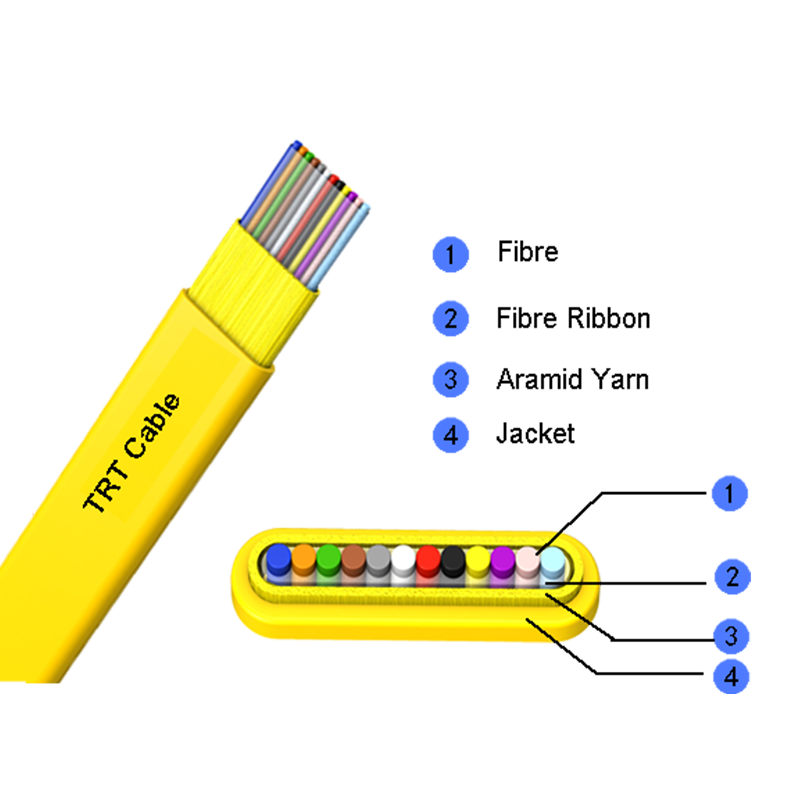

Multi-Purpose Distribution Cable MPC≥24f

ABOUT US

Suzhou TeRuiTong Communication Co., Ltd.

Suzhou TeRuiTong Communication Co., Ltd. is China Custom Optical Fiber Cables Manufacturers and Optical Cable Assemblies Suppliers, located in the Wuzhong District, Suzhou, Jiangsu Province, China. It specializes in producing all kinds of indoor optical cables and also can develop the products according to customers' requirements. Our main products include indoor cable, outdoor cable, FTTH cable, flexible metal armored cable, a range of jumper wires and cable accessories which are all with the ISO9001&ISO14000 QS Certification.

The products are widely used in various fields, such as the computer room's construction of China Telecom and China Mobile, the networking engineering of buildings, the radio network, defense communications and shipping communications. We are introduced to the following fields civil engineering, bridge construction, electric power systems, subway temperature and straining sensing through wide sensor equipment and professional communication companies. We offer Universal Optical Fiber Cable for sale. We are confident that we have the experience to be your long-term strategic partner. Let us join hands and build a brighter future!-

Data centers are the backbone of modern digital infrastructure, handling everything from cloud computing to data storage, network traffic, and high-sp...

READ MORE -

Introduction Fiber optic cables are the backbone of modern communication networks, enabling high-speed data transmission over long distances. Two of t...

READ MORE -

Duct butterfly drop fiber optic cable is widely used in modern fiber-to-the-home (FTTH) networks and other high-speed communication infrastructures. S...

READ MORE -

Low friction FTTH indoor fiber optic cable has become an essential component in modern home networking solutions. As homeowners demand higher internet...

READ MORE

In the process of fiber optic cable braiding, how to ensure that the density, length, stretch and other parameters of multiple optical fibers meet the standards to ensure the stability and quality of the optical cable core?

During the design stage of fiber optic cable assemblies, Suzhou Teruitong Communication Co., Ltd. fully considered the key parameters such as the density, length and tensile performance of the optical fiber. Through advanced computer-aided design (CAD) and simulation software, the company's engineers can accurately calculate the optimal arrangement of optical fibers and the required materials for different application scenarios, thereby optimizing costs while ensuring performance. In terms of material selection, the company strictly selects high-quality glass fiber and plastic sheath materials, which not only have good optical properties and mechanical strength, but also maintain stable performance in extreme environments, laying a solid foundation for the stability and quality of optical fibers.

During the production process, Suzhou Teruitong Communication Co., Ltd. is equipped with top production equipment in the industry, including 14 multifunctional and diversified flexible optical cable production lines, 8 indoor introduction universal optical fiber cable production lines, and 2 outdoor sheath production lines. These production lines all use advanced automatic control systems and precision mechanical devices, which can achieve precise control of key links such as optical fiber arrangement, tension control, and length measurement.

Fiber arrangement and density control: Through high-precision fiber arrangement devices, the company can ensure that each fiber is accurately positioned in the optical fiber cable. At the same time, laser ranging and image recognition technology are used to monitor the fiber arrangement density in real time to ensure that it remains constant throughout the production process.

Length control: On the production line, the length of the optical fiber is monitored and adjusted in real time through a precise metering system and tension controller to ensure that the length of each optical fiber meets the design requirements and avoid signal attenuation or transmission quality problems caused by length deviation.

Tensile performance test: During the production process, the company will also conduct multiple tensile performance tests on the optical fiber. By simulating the tensile conditions in actual use, the strength and durability of the optical fiber are evaluated to ensure that it will not break or degrade in performance during long-term use.

In addition to implementing strict process control during the production process, Suzhou Teruitong Communication Co., Ltd. has also established a complete quality inspection system to ensure that each batch of optical fiber cable assemblies meets international and industry standards as well as customer-specific requirements.

Online testing: On the production line, the company has installed multiple sets of online testing equipment, including fiber loss testers, fiber length measuring instruments, tensile testing machines, etc. These devices can monitor the various performance indicators of optical fibers in real time. Once an abnormality is found, an alarm will be immediately issued and production parameters will be automatically adjusted to ensure product quality.

Full inspection of finished products: For the final finished products, the company will conduct a full inspection according to customer requirements and international and industry standards, including appearance inspection, performance testing, environmental adaptability testing and other aspects to ensure that each optical fiber cable reaches the optimal state.

Top testing equipment: The company also has a complete range of top testing equipment in the industry, which can meet the comprehensive testing needs of various customers, including high-precision spectrum analyzers, optical time domain reflectometers (OTDR), etc. These devices can accurately measure key parameters such as optical fiber loss, attenuation coefficient, reflection, etc., providing a strong guarantee for further improvement of product quality.

In addition to standardized production processes and quality inspection systems, Suzhou Teruitong Communications Co., Ltd. also provides customers with customized products and services. In response to the needs of different industries and specific application scenarios, the company can design fiber optic cable solutions that meet customer requirements and provide related supporting components and construction tools. At the same time, the company also has a professional technical support team that can provide customers with a full range of services from product design, production to installation and maintenance, ensuring that customers get the best experience during use.

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى-1.png)

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:

Email: